Circular economy

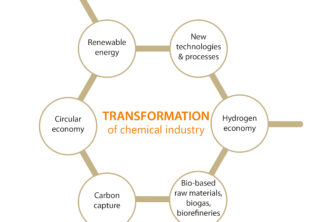

To kick off our series of articles on the sustainable transformation of the chemical industry, we first turned our attention to biobased raw materials, biogas plants and biorefineries, and then to the hydrogen economy. These are innovative areas that are currently undergoing major development. Next, we focus on the circular economy. Here we look at the status quo and examine projects that have already been implemented as well as those that are in the planning stage. We present initiatives and take a look into the future to see which approaches are important for a circular economy and where there are problems.

The circular economy currently accompanies us every day, also in form of a TV commercial. The Schwarz Group (Lidl) is advertising the “circular bottle” (Kreislaufflasche) with testimonial Günther Jauch on television and is thus receiving a great deal of attention. More later on the so-called “circular bottle”, as an example of a circular economy. What exactly do we mean by circular economy and where do the problems currently lie?

Germany is considered a nation of waste separation. These are good basic prerequisites for a circular economy, but we are still a long way from achieving it. Other countries, such as the Netherlands, are developing real circular strategies and are ahead of us.

The EU is also focusing on the circular economy as part of the so-called Green Deal (“Circular Economy Action Plan”). The aim is to develop procedures and processes in such a way that virtually no waste is generated in the first place. Germany has had a circular economy law since 1996. However, the German term “Kreislaufwirtschaft” often only describes the separation and recycling of waste, whereas the English translation of the term, the “circular economy”, encompasses more than just waste management. A sustainable circular economy describes a cycle of recyclable materials that starts with the design of products. Here, waste is seen not just as garbage, but rather as an accumulation of recyclable materials that should be put back into circulation.

The circular economy is a sustainable counter-model to the currently prevailing linear economy, in which a large proportion of the raw materials used are still landfilled or incinerated after the useful life of the products and thus removed from the cycle of recyclable materials. The turning away from a purely linear economic approach including the steps of exploration, production, consumption, and disposal represents a paradigm shift.

The circular economy aims to overcome the linear model and limits the resources in circulation. In doing so, it puts the brakes on the usual business model, which relies on constantly growing sales of physical products. The goal of the circular economy is to increase resource efficiency along the entire value chain, always keeping in mind that the planet’s resources are finite. The high consumption of resources as well as the climate change require a rethinking of the economy and society. The circular economy is an important component on the path to climate neutrality, as the primary goal is to decouple economic growth from resource consumption. It works on the principle of “produce, use, recycle” and knows several strategies of so-called (re)utilization: reuse, repair or remanufacture.

According to the “Circle Economy” organization, only 7 percent of resources in the global economy are currently reused. In 2018, the year of the first Circularity Gap Report, this figure was still more than 9 percent. The recyclability of the global economy currently continues to decline. In contrast, the overall rate of global material extraction is increasing. In addition, more and more materials are going into stockpiles such as roads, houses and durable goods, and fewer materials can be recycled back into the economic cycle.

However, an economy that focuses solely on recycling cannot keep up with the consumption of virgin materials, which is increasing to unprecedented heights. It is obvious that recycling alone is not enough to meet this challenge. In Germany, the circular economy could reach a market volume of up to 200 billion euros by 2030, according to the Boston Consulting Group. For Europe, the market volume is even expected to reach 800 billion euros. Estimates from McKinsey see the market as being significantly larger at 1,800 billion euros. So why is this enormous potential not being exploited? Apart from various hurdles that stand in the way of the circular economy, the answer is unfortunately quite simple. Sustainable raw materials are not profitable enough. Until now, it has been more efficient and cheaper to extract raw materials from the earth than to recycle and recover them. The circular economy has not been profitable so far.

What other hurdles does the circular economy face?

- While the circular economy is focused on long-term time perspectives, companies operate on much shorter time scales, from quarter to quarter.

- External factors:

Lack of willingness to cooperate from upstream and downstream stages in the supply chain.

Cooperation is prevented, for example, by legislators through antitrust laws.

Laws restrict the development of the circular economy at many levels, e.g., the transport of waste within the EU. - Prevailing culture of cheap consumption (Black Friday, etc.):

Environmental costs are not reflected in products.

Products from the linear economy are cheaper than those from the circular economy.

Despite the many obstacles the circular economy is facing, awareness in the industry is increasingly changing, because availability and access to resources are becoming some of the greatest business risks for the industry and for Germany and Europe as a business location. Securing raw materials has become one of the most important prerequisites for ensuring that the energy transition succeeds and that the path to climate neutrality is successfully taken.

A circular economy creates the necessary access to important materials and resources that are already in the country. According to the Boston Consulting Group, investments of 50 to 60 billion euros are needed by 2040 to achieve a 75 percent recycling or circular economy for many materials in Germany. We are currently still a long way from achieving this goal. Thanks to the recycling of deposit bottles and wastepaper, the rate is still around 12 percent. Although Germany is the world champion in recycling and has built up one of the best waste management infrastructures, it is lagging behind in the circular economy.

The chemical industry has long recognized the circular economy as an opportunity. One way to significantly reduce the carbon footprint is to no longer obtain carbon from fossil raw materials, but from waste plastics and recycled materials, plants or carbon dioxide. The current setup of the chemical industry is still heavily based on fossil resources. However, the chemical industry will be able to accelerate the circular economy through innovative processes such as chemical recycling. Chemical recycling represents an important approach to promoting resource efficiency and emissions prevention. In this process, for example, plastic waste is broken down into its basic chemical components, which can be used as raw materials in the manufacture of new products.

European plastics manufacturers plan to invest 2.6 billion euros in chemical recycling by 2025 and 7.2 billion euros by 2030. Production is expected to increase from 1.2 million tons (2025) to 3.4 million tons (2030) of recycled plastics. This investment supports the Circular Plastics Alliance’s (CPA) goal of bringing 10 million tons of recycled plastics for new products to the European market by 2025. Member companies of the European Plastics Producers Association are planning 44 chemical recycling projects in 13 different European countries.

Let us now take a look at selected companies in the German chemical industry. What statements (presented in abbreviated form) are made regarding the circular economy:

- BASF: BASF has launched a program to double sales of circular economy solutions to 17 billion euros by 2030. The three fields of action on which BASF is focusing are the use of circular raw materials, new material cycles and new business models. By 2025, the company plans to process 250,000 tons of recycled and waste-based raw materials annually instead of fossil raw materials.

- Covestro: Covestro plans to fully align itself to the circular economy and to take a leading role in the plastics industry. Plastics are highly important for a circular economy. Covestro is striving to become the shaping force for the entire industry as the circular economy becomes the new guiding principle for companies worldwide.

- LANXESS: LANXESS is using the EU Commission’s Green Deal action plan as an innovation driver for the circular economy, adapting products and materials to meet higher recycling requirements. The company is working with buyers to develop safe and sustainable product designs and manufacturing processes and become an even more sustainable partner for its customers. LANXESS is increasing its use of biobased or recycled raw materials in plastics production to further advance the circular economy.

- Evonik: Evonik’s Global Circular Plastics Program bundles circular activities along the entire plastics value chain throughout the group. The program comprises short- to medium-term projects aimed at commercialization and including, for example, the use of circular raw materials, the development of recycling technologies and the creation of innovative business models. Partnerships and value chain reviews are important keys to supporting the transformation to circular economies. The company expects additional sales of more than 350 million euros per year from the Global Circular Plastics Program from 2030 onwards.

Below are some examples from the chemical industry that deal with recyclable products. In addition to these, there are many other interesting approaches.

PET bottle (LIDL): In Germany, LIDL has launched a comprehensive “For the love of nature” campaign to promote the ecological benefits of the circular bottle (“Kreislaufflasche”), which is made from 100 percent recycled PET plastic. A new life cycle assessment, prepared by the Institut für Energie- und Umweltforschung (Ifeu) shows that the circular bottle is one of the most ecological bottles compared to the reusable bottles commonly available on the market. The recycled material can also be used for other purposes, including the production of textiles. www.diekreislaufflasche.de

Mattresses (BASF, Covestro, DOW, Evonik, etc.): Companies from the chemical industry and research institutes are working to establish a closed product cycle for mattresses. In Europe, approximately 30 million mattresses are thrown away each year. Currently, of the approximately 450,000 metric tons of used mattresses per year, 40 percent go to incineration and 60 percent to landfill. About one-third of the world’s production of polyurethanes (PU) is used to make flexible foams such as mattresses, cushions, and seat upholstery in the automotive and aerospace industries. Polyurethanes are chemical condensation products of isocyanates and polyols. To recycle PU foams, a chemical solvolysis process has been developed as part of the European research project URBANREC. Currently, chemical companies have started pilot plants and are cooperating with other companies along the value chain. On the way to a closed loop, the systematic collection and return of end-of-life mattresses is an important element that already starts with the product design of mattresses. To facilitate this return, NEVEON has launched REMATTRESS, a mattress take-back pilot in Berlin.

Pyrolysis oil (BASF): Around 250 million metric tons of plastic waste are generated worldwide every year. Only 20 percent is recycled and thus kept in the material cycle. In order to establish a circular economy for plastics, BASF, for example, has launched the ChemCycling® project. Together with other partners, this project is working on improving pyrolysis technology in the field of chemical recycling. This technology enables the extraction of pyrolysis oil from plastic waste or used tires as a secondary raw material. This oil is fed into BASF’s integrated production at the beginning of the value chain, thus saving fossil resources. The cleantech company Pyrum plans to build 50 tire pyrolysis reactors over the next five years to produce pyrolysis oil from used tires. A first plant has already been running since 2020, processing 3,000 waste tires a day. More than 600,000 tons of scrap tires are generated in Germany each year. The company estimates the volume worldwide at 39 billion euros. Mercedes-Benz aims to increase the proportion of recycled materials in its passenger car fleet to around 40 percent by 2030. In the area of scrap tires, the company is cooperating with Pyrum. BASF has taken a financial stake in Pyrum and plans to purchase 100,000 tons of pyrolysis oil per year.

Battery materials (BASF): A plant for the large-scale recycling of black mass from batteries is currently being built at the Schwarzheide site. Around 15,000 metric tons of electric vehicle (EV) batteries and materials are to be processed annually. What is black mass? Black mass is what remains after a battery has been treated for recycling. Batteries are made of metals such as lithium, manganese, cobalt and nickel. When the battery reaches the end of its life, it is collected, disassembled, and shredded. The shredded material is treated to produce black mass, which contains a lot of these metals. These critical materials can be extracted from the black mass and reused in the manufacture of new batteries or new products and/or applications. With battery recycling, BASF aims to close the loop from used batteries to cathode materials for new batteries with a lower carbon footprint. In this effort, BASF is collaborating with Tenova Advanced Technologies, a company specializing in sustainable solutions for the green transition in the metals industry. The future market for battery recycling is gigantic.

In just 8 years, global demand for EV batteries is expected to increase tenfold from 340 GWh (2022) to 3,500 GWh (2030). Both battery manufacturers themselves and companies specializing in raw material extraction and recycling are increasingly investing in EV battery recycling. Most recycling and production facilities in Europe are currently in the project and construction phase. The EU’s estimated 2.5 megatons of new batteries by 2030 will require a growing number of recycling facilities. By 2030, annual recycling capacity could reach more than 1,100 GWh if all European recycling plants come on stream. Germany is currently playing a pioneering role in Europe in this respect.

These are just four examples, but they show what initial approaches to the circularity of products could look like in the future. The list of possible circular products such as wind turbines, photovoltaic modules, phosphorus recycling in wastewater treatment plants, but also textiles and other consumer goods can be continued at will.

Let’s now take a brief look at selected initiatives in the field of the circular economy:

- ERDE (Erntekunststoffe Recycling Deutschland) is a take-back concept for so-called harvest plastics from agriculture. www.erde-recycling.de

- The Ellen MacArthur Foundation is a charity that promotes the circular economy. In addition to raw material producers, retail chains and brand manufacturers, the packaging industry is also represented here. www.ellenmacarthurfoundation.org/

- The Loop Initiative was launched in January 2019 at the World Economic Forum in Davos. Loop is a global reuse platform maintained by a coalition of manufacturers, retailers, and consumers with the goal of eliminating the idea of waste. www.exploreloop.com/

- The Alliance to End Plastic Waste is an industry-founded and funded non-governmental, non-profit organization. Founding members include BASF, ExxonMobil, DOW, Procter&Gamble, among others. The Alliance has four focus areas: Implement and develop circular economy infrastructures, advance, and educate about innovative technologies and solutions, and eliminate plastic waste from the environment. www.endplasticwaste.org/

- The Ceflex project was launched by more than 30 companies covering the entire flexible packaging value chain. The goal is to increase the contribution of flexible packaging to the circular economy and develop new system design solutions. www.ceflex.eu/

- Circular Plastics Alliance – The alliance aims to increase the EU market for recycled plastics to 10 million tons by 2025. It covers the entire plastics value chain and includes over 300 organizations from industry, academia, and authorities. www.circular-plastics-alliance.com/

- CIRCULAR FoodPack – The research project aims to recycle food packaging in a closed loop and make it usable for direct food contact. Innovative monomaterial packaging is being developed that is not inferior to multilayer composites in terms of its protective function but enables closed-loop recycling and reuse. www.circular-foodpack.eu/

- Circular Economy Initiative Deutschland (CEID) has set itself the goal of creating a roadmap for a sustainable circular economy in Germany. Stakeholders from business, science and civil society are working together in the initiative to achieve this mission by showing new ways to a circular economy. www.circular-economy-initiative.de

What are the approaches and demands from the chemical industry for a future circular economy?

For this purpose, the sustainability initiative Chemie³ has produced the guideline “Entry into the circular economy in the chemical industry”. More than 30 companies from the German chemical industry have contributed to this guide. It is intended to serve as a practical guide for companies in the chemical and pharmaceutical industry to convert to a circular economy. Included are business solutions and case studies that offer practical benefits. The guide aims to motivate medium-sized companies to take advantage of the opportunities offered by the circular economy and to reduce barriers to entry through pragmatic approaches and proposed solutions.

The core statements relevant to a future circular economy are listed below:

There is no alternative to the circular economy

The linear economy has had its day because we can no longer afford this way of doing business in the future. In order to save resources, there is no alternative to the circular economy. Here, all participants in the supply chain must be brought on board, from the manufacturer to the distributor, to the customer, to the disposer and recycler of the used products. Short-lived products have had their day. The circular economy requires products that are durable and easily recyclable. Used raw materials remain in the cycle for a long time, serve as new raw materials after use and do not become waste. In some cases, this requires new material cycles and new business models.

What will the products of the future have to look like? Product design plays a decisive role in the circular economy. More than 80 percent of the environmental impact of products is defined in the design phase. Products and their components or materials must be reusable and, above all, recyclable for circular product design. Complex products should be tested and developed for these criteria right from the start. In the future, the common production principles must be supplemented by the “Design for R” principle. Here, “R” stands for Reuse, Repair, Remanufacture, Recycle. Maximum recycling of products will be the focus in the future.

The chemical industry has a key role to play here, with its proven processes such as solvo- and chemolysis, future novel processes, new material cycles or entirely new business models. Chemical companies are already testing new models for “leasing” chemicals, advanced recycling technologies and converting solid waste into hydrogen. This shows that the pace of innovation is increasing significantly. However, proving that these pilots are commercially viable at scale will require significant long-term investment in research and development, infrastructure development, and collaboration with new upstream and downstream players. The industry is still in the early stages of establishing a recycling economy to achieve the goal of a circular economy.

However, on the path to a carbon-neutral industry, the circular economy is the only alternative and represents society’s largest transformation project. SVP expects that the pace of innovation will continue to accelerate and that we will see more and more new approaches and product examples of a circular economy in the near future.

In the next article, my colleague, Dr. Ronald Hinz, will address the topic of carbon capture and look at the projects that have already been implemented as well as those that are in the pipeline. What are the potentials and opportunities for the chemical industry and what are the current hurdles?

Dr. Volkhard Franke, Market Intelligence Senior Expert

Sources:

- Circle Economy „The Circularity Gap Report 2023” https://www.circularity-gap.world/2023;

- DKE www.dke.de;

- VCI www.vci.de/themen/zirkulaere-wirtschaft/uebersicht.jsp;

- Chemie³ www.chemiehoch3.de/handlungshilfen/leitfaden-kreislaufwirtschaft/;

- Universität St. Gallen www.unisg.ch/de;

- Webseiten von BASF, Evonik, Covestro, Lanxess;

- MHP www.mhp.com/de/insights/sustainability-blog/fuenf-impulse-fuer-die-erfolgreiche-transformation-zu-circular-economy;

- Aboutdrinks www.about-drinks.com/kreislaufflasche-lidl-startet-kampagne-aus-liebe-zur-natur/;

- EUWID www.euwid-recycling.de;

- Eurostat https://ec.europa.eu/eurostat/web/circular-economy/publications;

- KPMG “Sustainable Batteries”, 2023 www.kpmg.com ;

- Plastics Europe “The Circular Economy for Plastics – A European Overview” www.plasticseurope.org